Expanded Metal in All Patterns and Materials for Your Choice

In industrial production, there is a lot of waste. However, expanded metal solves the problem well. Because expanded metal is manufactured by slitting and stretching the metal sheet with a die creating different shaped holes in one step, which makes it more economical. Due to formed from a piece of metal, there are no welds or weak points, which make its structure more sounder than other type metals.

:Regular expanded metal

has anti-slip surface as it is cut and stretched into diamond openings.

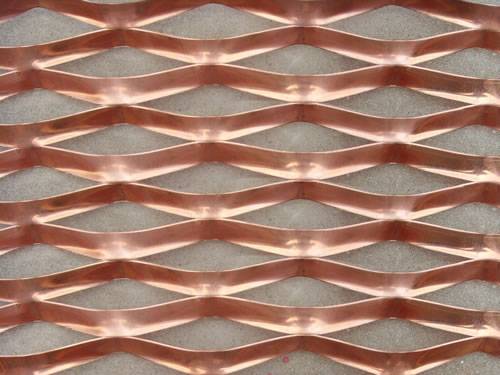

:Regular expanded metal

has anti-slip surface as it is cut and stretched into diamond openings.

Regular expanded metal

has anti-slip surface as it is cut and stretched into diamond openings.

Regular expanded metal

has anti-slip surface as it is cut and stretched into diamond openings.