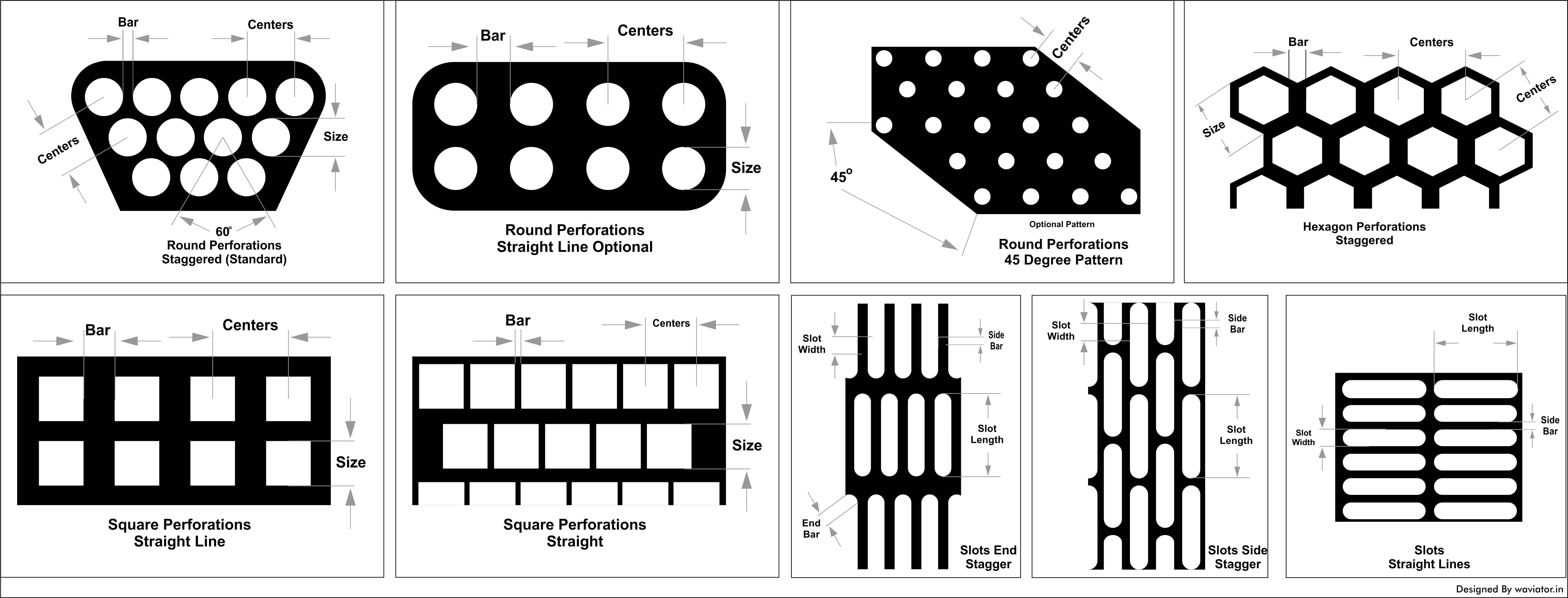

Perforated Sheets Metal in All Patterns and Materials for Your Choice

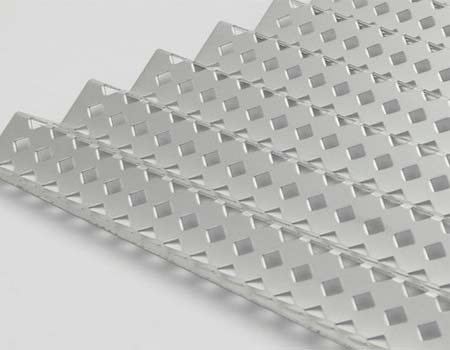

In industrial production, there is a lot of waste. However, expanded metal solves the problem well. Because expanded metal is manufactured by slitting and stretching the metal sheet with a die creating different shaped holes in one step, which makes it more economical. Due to formed from a piece of metal, there are no welds or weak points, which make its structure more sounder than other type metals.

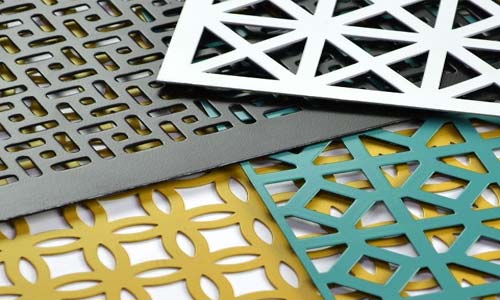

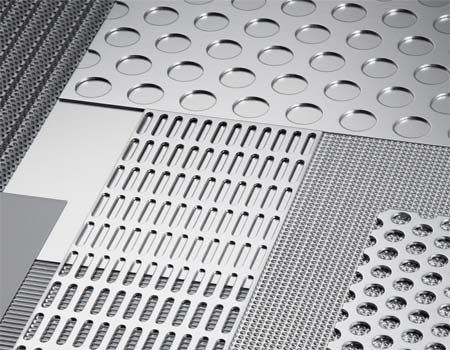

Light Perforated sheet.

Light Perforated sheet. Heavy Perforated sheet.

Heavy Perforated sheet. Square Perforated sheet.

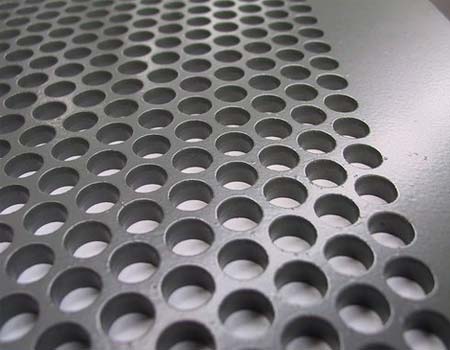

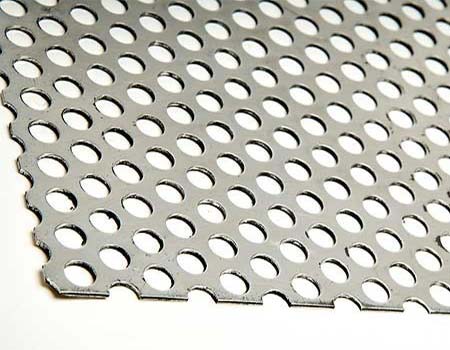

Square Perforated sheet. Round Perforated sheet.

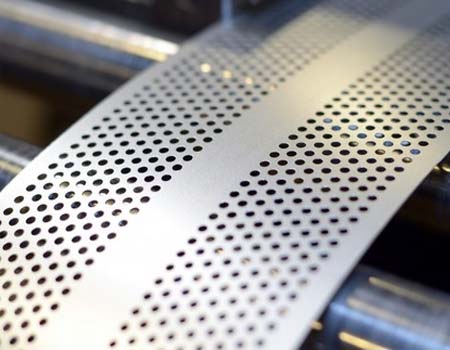

Round Perforated sheet. Long Perforated sheet.

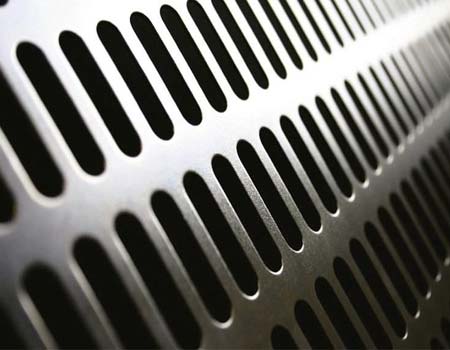

Long Perforated sheet. Capsule Perforated sheet.

Capsule Perforated sheet. Dimple Perforated sheet.

Dimple Perforated sheet. Kinetic Perforated sheet.

Kinetic Perforated sheet. Hexagonal Perforated sheet.

Hexagonal Perforated sheet. Trinagle Perforated sheet.

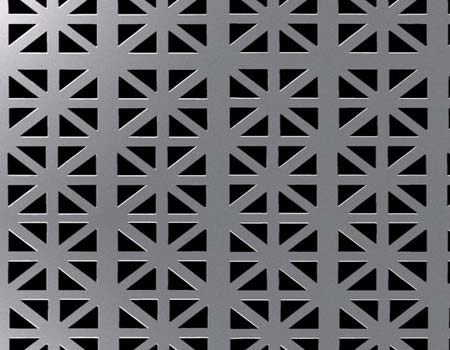

Trinagle Perforated sheet. Manufacturer Perforated sheet.

Manufacturer Perforated sheet. Staggered Perforated sheet.

Staggered Perforated sheet.