Flattened Expanded Metal – Lightweight, Economical and Versatile

Flattened expanded metal, is manufactured by passing the metal through a cold

roll reducing mill parallel to the LWD. It is Standard Expanded Metal that has been

rolled through a flattening machine in the expanding process. By flattening the sheet,

the bonds and strands are turned down to produce a smooth and flat surface – essentially

elongating the LWD of the diamond. Flattened Expanded Metal with versatile and be bent

or formed in any direction is used in billboard walkways, catwalks, stairs, drying

racks, vents, ramps, walkways, flooring.

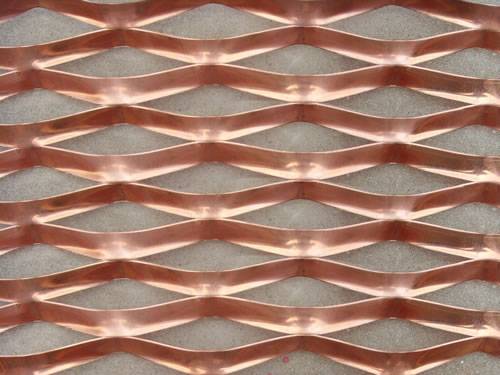

Flattened expended metal with various colors can be used for decoration.

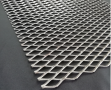

Specification of Flattened expanded metal:

- Materials: stainless steel, carbon steel, brass, aluminum, nickel, Al-Mg

alloy.

Features of Expanded Metal Features:

- Lightweight

- Economical

- Versatile

- Low Maintenance.

- Can be bent or formed in any direction.

- U-edging for finished edges.

Application:

Flattened expanded metal is widely used as panels, screens, railings, security

partitions, reinforcement, gratings, window guards, anti-dazzle screens, fencing,

grilles and in billboard walkways, catwalks, stairs, drying racks, vents, ramps,

walkways, flooring.

Garden furniture is the

most popular application for flattened expanded metal, which is strong enough and

economical.

One of flattened

expanded metal applications is the bike basket, which is strong enough to hold many

goods.

Garden furniture is the

most popular application for flattened expanded metal, which is strong enough and

economical.

Garden furniture is the

most popular application for flattened expanded metal, which is strong enough and

economical.

One of flattened

expanded metal applications is the bike basket, which is strong enough to hold many

goods.

One of flattened

expanded metal applications is the bike basket, which is strong enough to hold many

goods.